Tailing dams and trailing slams

Global Industry Standard on Tailings Management released; tailing dams as an enduring responsibility

Tailing dam management is vastly improved compared to, really, any past period – the problem, however, is how long-lived they are. Tailing dams are one of the first things built at a site, are used and expanded extensively throughout production, and remain effectively forever.

Every engineer or mining professional knows a few tailing dam horror stories off the top of their head.

-

2019’s Vale Brumadinho tailing dam collapse in Brazil. The death toll of 270 is approximate as some bodies have never been recovered. The company’s CEO and 10 others from the mining company Vale have been charged with homicide, charges that have also been levied against a TUV SUD auditor that certified the tailing dam. The video below shows the dam failure and mudslide starting through the mine site and beyond.

Vale's Brumadinho tailing dam collapse, in January 2019 Brazil (credit: The Guardian)

-

The 2010 Kolontár, Hungary bauxite mine tailing dam that collapsed after heavy rain that killed 10 people, injured 120 and flooded multiple towns. More than 1 million cubic metres of the caustic sludge destroyed houses, poisoned rivers and livestock, and burned skin. The company’s CEO was briefly gaoled. The mine was ‘upstream’ constructed (the dam structure built in part with the tailings), and failure foundationally caused by lack of understanding of fluid and materials mechanics. Entirely foreseeable and avoidable.

The broken dyke at Kolontár in Hungary, 4 days after the disaster (credit: The Atlantic)

-

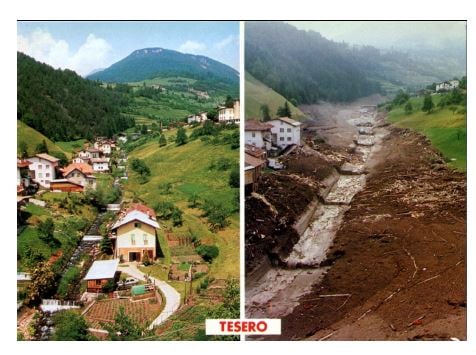

The 1985 Stava fluorite mine tailing dam in Italy, which collapsed due to poor design, poor construction and conditions it simply was not built to withstand. Entirely foreseeable and avoidable.

Before and after the Stava fluorite tailing dam collapse

Closer to home the Paradise Dam in the Wide Bay-Burnett – on the coast about halfway between Brisbane and Rockhampton – is subject of community alarm due to concerns about its structural integrity. A 580-page commission report tabled by in May 2020 in the Queensland state parliament confirmed the operator’s findings, that the dam needed to be reduced to 42% capacity. The government report found the dam's spillway fell "well below safety guidelines", meaning more than 100 people would be at risk if the dam failed.

Paradise Dam in Queensland (credit: InQueensland)

Paradise Dam in Queensland (credit: InQueensland)

Tailings dams skyrocketed in use after about 1950, so in addition to newer ones like Paradise Dam (created in just 2005) there’s many older dams – a majority of the estimated 3,500 tailing dams worldwide no longer serve active mines. According to Richard Williams of process engineering specialists McLanahan’s International, “there are one or two tailings dam failures a year.” The industry’s consideration of tailing dams was sharpened after the Vale Brumadinho failure in Brazil, but these dams had long been recognised as a source of hazard. Tailing dams are inherently complex and dynamic in nature, with chemical and structural composition continually changing as ore composition and processing additives vary.

So, the new Global Industry Standard on Tailings Management is relevant and timely. The standard addresses tailing dam oversight in three phases – pre-construction and initial embankments, operational phase and closure and rehabilitation. Numerous tests need to be conducted through these phases, such as the sampling of dam water composition from up and down stream and piezometer ground water pressure levels. The report also detailed the difficulty in monitoring dam structures, many parts of which are difficult or impossible to see or scan unaided.

This where a drone data collection, drone-mounted sensors and big data historical and predictive analysis takes flight! Puns aside, close visual inspection via drone, ultra-accurate lidar based mapping and asset management are typical drone data collection targets. Less common drone mounted sensors [link to other blog] include non-lidar photonic, pressure, audiometric, chemical, PZT and even FBG sensors. In context of the Global Industry Standard on Tailings Management, it is recommended that close visual inspection of the dam and slipway wall, as well as all embankments, be conducted routinely throughout the operational and mine closure/rehab part of the dam’s life. Lidar mapping is recommended, to get a view beneath vegetation that may obscure parts of the structure. Ambient analysis of air quality and gas concentration is also recommended throughout the dam’s lifecycle.

Similar audits would have likely alerted authorities to the imminent 2015 collapse of the Samarco and Brumadinho dams, widening group aware of issues at both sites and potentially enabling workers and community to move to safety. Moreover, collection of regular inspection data could have fed a big data platform to inform works at those sites as well as others. In the wake of these tragedies, the Brazilian government made upstream dam construction illegal – but realistically many of these will continue to exist in Brazil and around the world for decades. In 2019 BHP announced that 32 of its 67 tailing dams were built using the upstream method and classified as ‘high risk or worse.’ Four of the five ‘extreme risk’ dams are in Australia – Mt Whaleback iron ore mine in WA and three at Olympic Dam in South Australia. Extreme risk signifies the potential loss of life would exceed 100 people and that there would be major environmental, cultural, infrastructure and economic damage. Close visual inspection mapping and pooling of that data to create a robust predictive tool will be important to manage upstream-constructed dams in particular, throughout their lifecycles.

Drone analysis of tailing dams, using lidar and high resolution imagery, would significantly aid managers to manage risks and protect communities and environments. This and similar solutions should be built into lifetime dam management, according to the Global Industry Standard on Tailing Management, as part of the resource company’s enduring responsibility.

Discover how drone data collection at mine sites will deliver far greater detail and support more robust decision making, more cost efficiently.